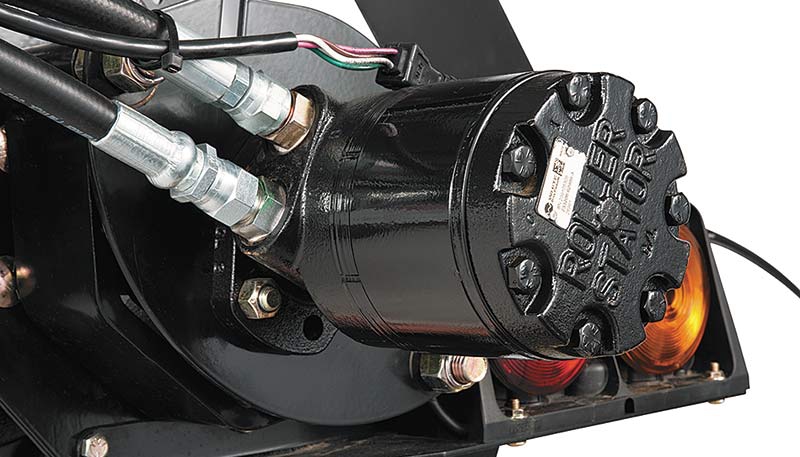

WS Grain Belt Swather

Maximize Machinery Efficiency

Honey Bee lives to make harvests faster and more efficient. If you have a self-propelled haying windrower, the WS Grain Belt Swather table will turn your John Deere power unit into a high-efficiency swather, reducing machinery capital costs and increasing your farming productivity.

Built on a platform that easily attaches to a John Deere windrower, and with increased durability features such as a heavy-duty 3/16″ tubular steel header mainframe, the WS Grain Belt Swather is designed to last. Available in widths from 21’ to 36', its high capacity is optimal for improved flow of specialty crops like canola. A simple coupling and uncoupling procedure makes the swather easy to transport down narrow roads.

Features

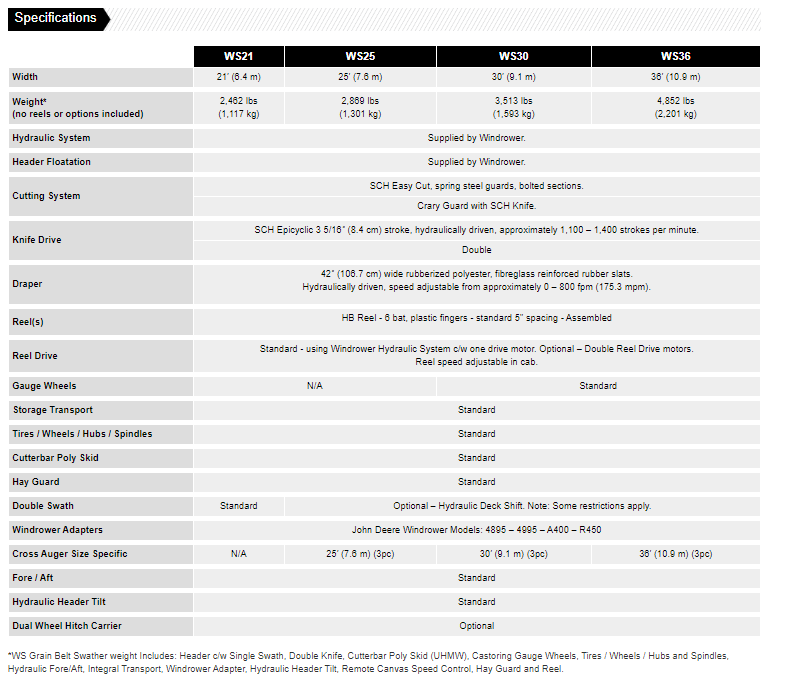

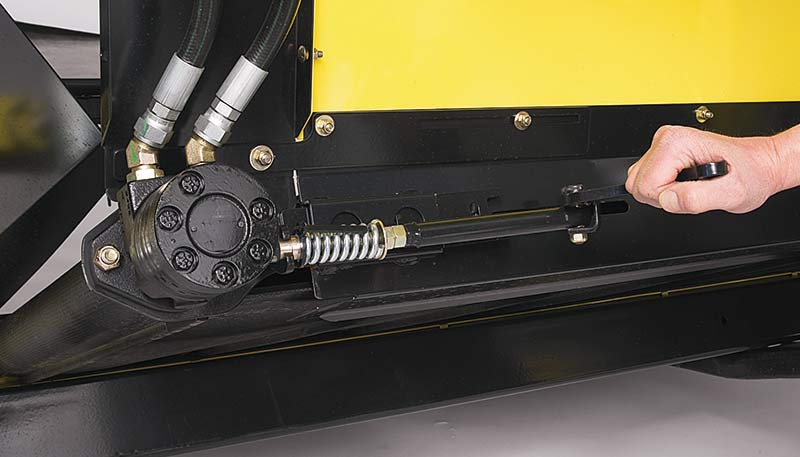

Remote Draper Speed Control

Draper speeds are hydraulically controlled in-cab, and are adjustable up to 800 rpm. Remote draper speed control gives you the power to quickly adjust draper speeds for varying crop conditions.

Polyester Drapers

42″ (106.7 cm) drapers are made of long-lasting, rubberized polyester with fibreglass-reinforced slats and are V-guided to eliminate manual draper tracking.

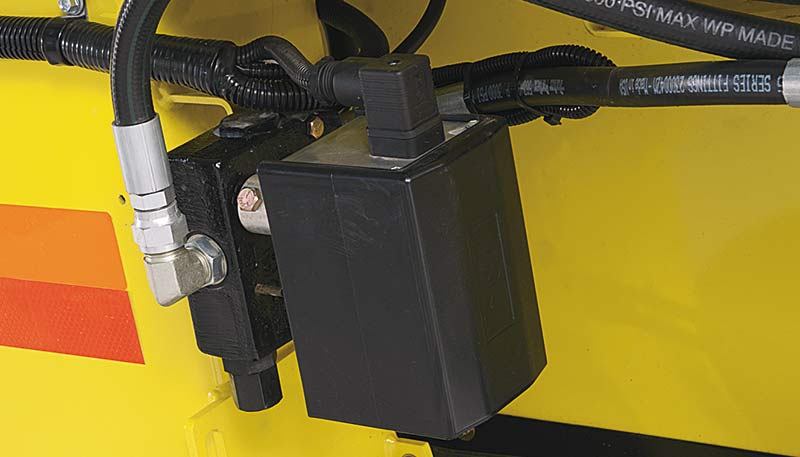

Draper Drive

The 3″ (7.6 cm) diameter drive rollers provide traction in heavy crop conditions. Powered from the outside by a hydraulic motor, the drapers move the crop towards the centre for more uniform feeding.

Reel Drive

The hydraulically driven reel is easily controlled using standard in-cab controls. In-cab controls allow for quick reel adjustment in changing crop conditions.

Hydraulic Header Tilt

No-wrench header tilt adjustment for header tilt control in varying crop conditions.

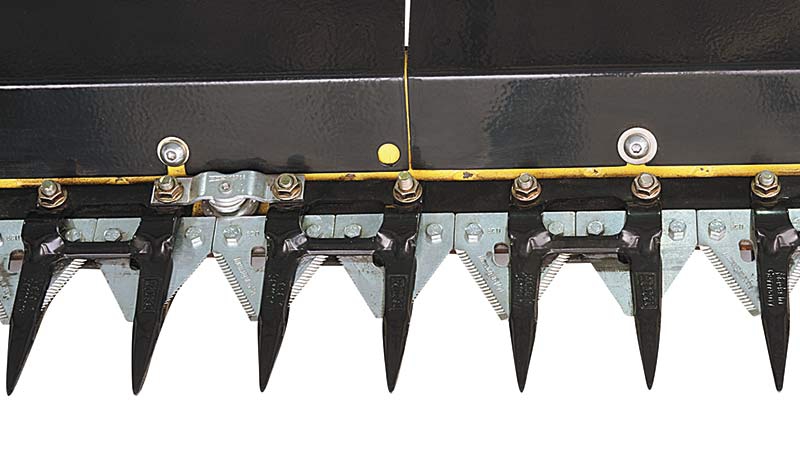

SCH Cutting System

The SCH Easy Cut Cutting System provides smooth, superior cutting. Spring steel guards with cutting edges on top and bottom, along with alternating, bolted, heat-treated sections, eliminate the need for hold downs. The system keeps dirt and debris from accumulating under the knives for increased performance in severe cutting conditions.

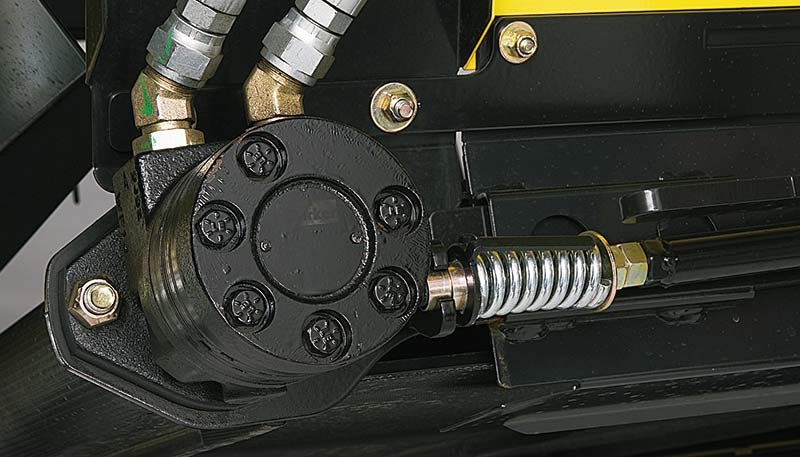

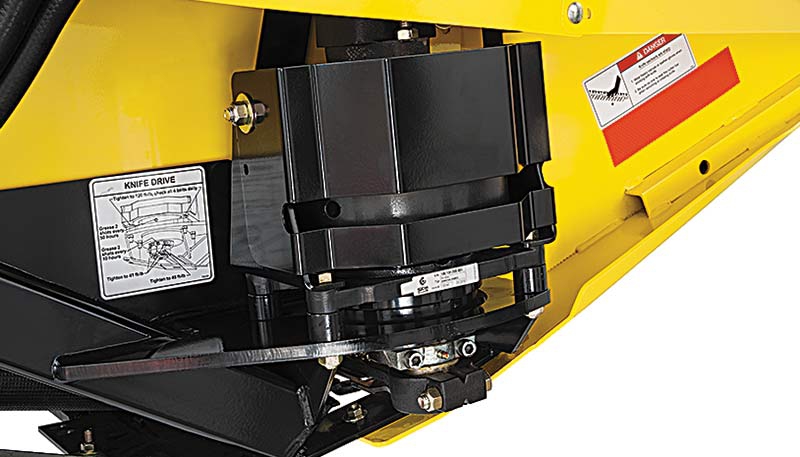

Knife Drive

The knife is driven by a 3 5/16″ (8.4 cm) stroke, epicyclic knife drive which operates from 1,100–1,400 strokes per minute. The knife drive is driven by a low maintenance hydraulic drive motor. Double knife drive systems are available optional equipment on 25′, 30′ and 36′ models. Standard equipment on 21′.

Fore/Aft Reel Adjustment

A hydraulic adjustment with in-cab control is available for fore/aft positioning for on-the-go response to changing crop conditions with a 16″ operating range.

Skid Plates

UHMW skid plates are standard on all models to protect the cutterbar when cutting crops close to the ground.

Swath Opening

Standard swath opening is 81″ +/- 3″. Double swath standard opening of 46″ +/- 6″. Standard swath opening may be decreased by 14″ or 28″ on some models.

Draper Tension and Tracking

The canvas can be adjusted for tracking and tightening, which allows for even tension on both the front and rear of the rollers. A quick release lever allows for ease of canvas and roller cleaning.

Easy Hook-up Lift Arm Extensions

Lift arm extensions attach to the windrower lift arm using a bolt. The lift arm assembly attaches to the swather using a “no-wrench” single pin attachment. New arms provide for an easy attachment and detachment of the table.

Integral Storage Transport

The self-contained transport, including hitch, jack and axle, is conveniently stored on the swather table.

Hay Guard

The Hay guard ensures a smooth transition from knife to draper and reduces material wrapping on the rollers.